In 2022, three new hybrid ro-ro vessels in the Eco-class entered Finnlines’ traffic. Sailing under the Finnish flag, they are called Finneco I, Finneco II and Finneco III.

While the EU aims to reduce emissions by 55 % by 2030, the International Maritime Organization (IMO) has set a goal of zero emissions from international maritime traffic by 2050. Shipping companies have 26 years to reach this goal. In the development of maritime engineering, that is a short time.

Cool air wafts onto your face. It lowers the temperature of huge batteries lined up in the engine room of a hybrid ro-ro vessel, M/s Finneco II. The batteries are in white metal cabinets standing in long rows like library shelves with gangways running between them. A cold, bright light illuminates the whole space. The room is quiet, almost silent. The sight is reminiscent of a data centre except that now we are in the engine room of Finneco II, a Finnish cargo ship.

First engineer Fretzly Tiangha is representing the engine room.

The EU maritime emission trading scheme began in early 2024. Emissions trading cannot be a permanent solution, however; it can only temporarily help mitigate climate change. For maritime traffic, climate action is progressing in two ways: by shifting towards low or even zero-emission fuels and by developing new technologies.

Finnlines supports this transition towards greener shipping and participates in the development of low-emission maritime transport. Its new constructions are as environmentally efficient as possible.

Finneco I, Finneco II and Finneco III are the largest cargo ships on the Baltic Sea, and they boast new technology being introduced, tested and further developed. This is why you can find such large batteries in the Finneco II engine room.

- The capacity of the lithium-ion batteries on Finneco II is 5 MW. They are charged while sailing and then used while in port, reducing port emissions to zero, first motorman Tiangha explains.

Ship batteries are new technology, and using them has required the crew to learn new techniques.

- So far, the batteries have worked well,’ continues Tiangha.

- However, their new technology involves several safety issues. The battery room must not be allowed to warm up, so it is constantly being cooled. Especially in the summer, we must make sure the temperature doesn’t rise too high.

The concept planning of Finnlines’ new hybrid ro-ro vessels began in 2018, aiming to create the most environmentally friendly vessel to have ever operated on the Baltic Sea. Finnlines’ hybrid ro-ro vessels in the Eco-class run on low-emission fuel. The batteries in the engine room and 600 square metres of solar panels on the ship’s deck allow emissions to be reduced to zero while in port.

Environmental friendliness and energy efficiency have also been achieved by increasing the size of the ships. More cargo can then be carried on a single voyage. In comparison with Finnlines’ existing fleet, the transport capacity of these new vessels is almost 40 per cent higher.

The best place to get a picture of the dimensions of Finneco II is the cargo hold. At the beginning of March, it is empty due to the stevedoring strike at Finnish ports. Finneco II and its sister ships each measure 238 metres long with a beam of 34 metres. Each vessel has 5,800 lane metres, meaning it can carry approximately 400 trailers per voyage.

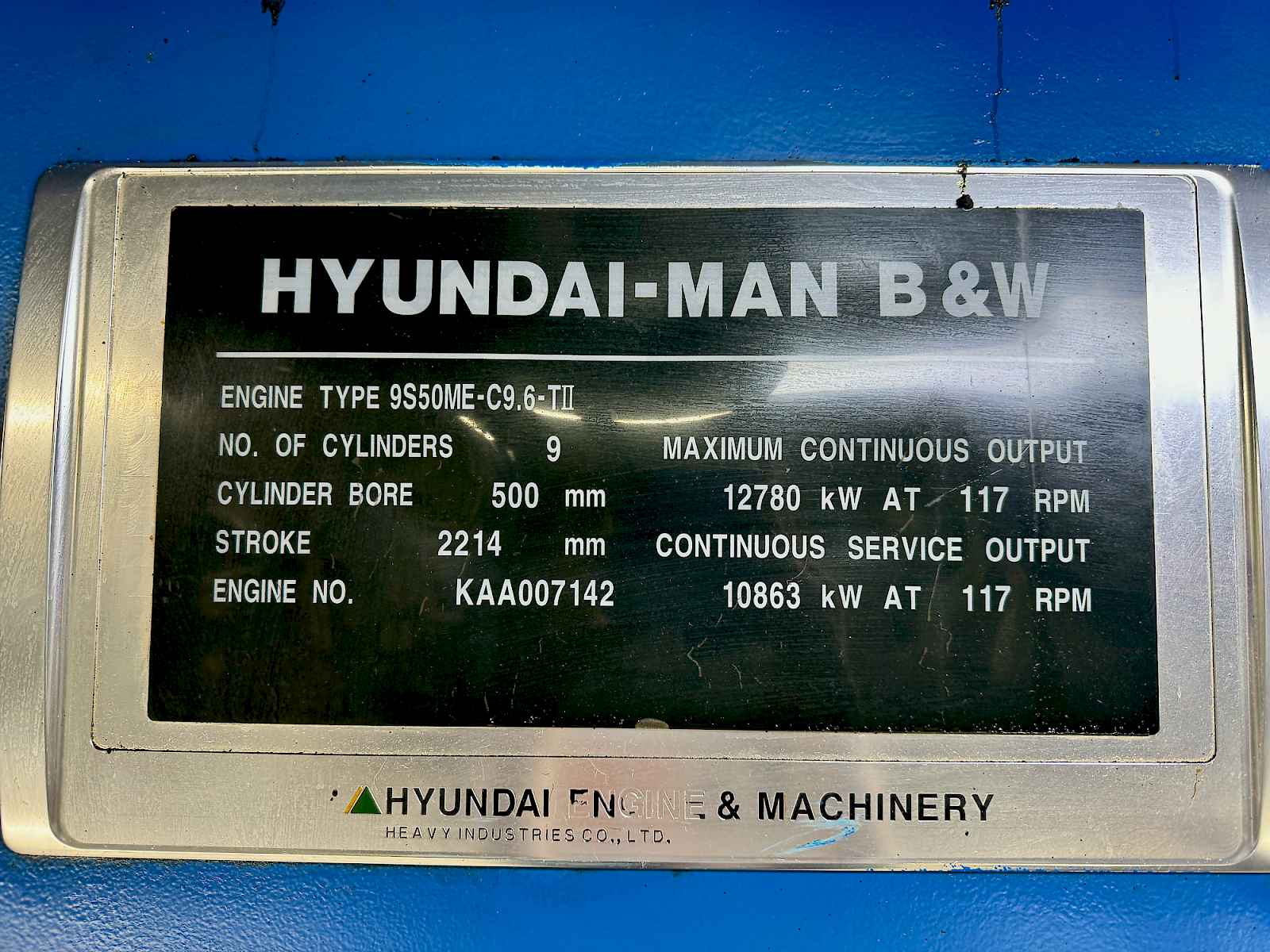

Finneco II is fitted with MAN propulsion engines. This type of engine was carefully chosen to achieve the lowest possible fuel consumption.

- The vessel has two main engines, both of them two-stroke. One engine has a power output of 12,780 kilowatts, meaning that for the pair of them, the power output is almost 30,000 kilowatts in total. As for the cylinders, there are nine of those,’ Chief Engineer Erkki Saar describes.

The vessel is powered by three generators. To abate emissions, it is fitted with sulphur scrubbers. The vessel also recovers heat.

Photo below: Air lubrication system: Silverstream Technologies compressors are installed in a room of their own towards the bow of the vessel.

The hull of the vessel is optimised to give it the ideal shape while the Promas Lite propulsion system helps improve the energy efficiency.

- Another speciality on our ship is the air lubrication system. It injects air bubbles underneath the bow of the ship to reduce the vessel’s friction and hydrodynamic resistance. This way, we can lessen the vessel’s fuel consumption, Saar explains.

Silverstream Technologies compressors are installed in a room of their own towards the bow of the vessel. The compressors are large with their adjacent piping passing down through the hull to generate air bubbles underneath. YouTube has a great animation showing this technology in more detail: Air lubrication for shipping – Introducing the Silverstream

Cargo handling has also been improved. Each vessel has several stern ramps and internal ramps as well as hoistable car decks. Certain areas of the cargo decks are specifically designed for loading paper rolls. Several decks and internal ramps speed up the process of loading or unloading. At the same time, these vessels are extremely flexible since the hoistable deck allows the ro-ro cargo a maximum height of up to seven metres.

Finneco II has a crew of 25 comprising Finns, Estonians and Filipinos. Tiangha has been working on the Baltic Sea since 2012 and knows the Finnish psyche relatively well.

- In comparison with Filipinos, Finns are calmer and sometimes a bit prone to just grunting, describes Tiangha, who acts as an intercultural mediator whenever new Filipinos join the crew.

Service at sea is something they will know through their vocational training, but they will not have been offered any kind of intercultural training by a shipping company. For a new Filipino sailor, learning and understanding the straightforward Finnish culture may be a real leap into the unknown. Having worked together with Finns for more than ten years, Tiangha is helping other Filipino crew members with intercultural communication.

- I often explain to new Filipino "crew" that they shouldn’t take it personally if a Finn seems to withdraw or give only the briefest of replies. That’s just the way Finns communicate, Tiangha says.

Creating a good working atmosphere and taking every worker into account with equality build the foundation for a well-functioning work community. In the Finneco II engine room, the spirit of a good work community seems palpable.

- It’s important for everyone to feel good at work and for the working atmosphere to be favourable,’ Tiangha declares. ‘Devoting efforts to a good team spirit is absolutely vital. Here in the engine room, we do everything we can to ensure a great sense of togetherness.

Whether from Finland, Estonia or the Philippines, the crew members in the Finneco II engine room maintain their team spirit in a chummy sort of way.

- It’s important to be open and polite to one another and considerate of everyone. Having a good work community starts with a sense of equality and respect for the other person, Tiangha says.

The engine crew have been servicing one of the ship engines all morning and acknowledging alarms while testing the systems. Now it is getting close to two in the afternoon and time for all the available engine crew members to get together for a game of UNO. This is the best example of how to build a good work community. You could take it anywhere!

- A good work community doesn’t just happen. You have to work at it, Tiangha says with wisdom.

- Having a game of UNO gives us a break from work. The whole engine crew can participate in this bit of recreation and thus strengthen its sense of togetherness.

The Filipinos spend six months working on this ship, so the quality of the working atmosphere is essential for coping at work. Now Finns, Estonians and Filipinos alike are gathering at the coffee table in the engine room for their regular game of UNO.

- Red six – and no cheating! It’s not a nine, someone shouts amid peals of laughter.

The game at the table demonstrates that compared to Finns, Filipinos are livelier and more outgoing. It also shows Finns and Estonians know how to joke around as well – albeit in ways of their own.

- All right then, here’s a challenge for you: a yellow three!, the next player exclaims.

The Finneco II engine room seems to be simply brimming with joy and brotherhood. It is a warm, authentic atmosphere you could not buy anywhere. To get it, you have to create it.